Pressure Die Casting Services

Aluminum pressure die cast products symbolizes precision engineering, offering lightweight yet durable components with exceptional strength and versatility.

Through advanced manufacturing techniques, our aluminum pressure die cast products deliver superior performance, reliability, and aesthetic appeal across diverse industries.

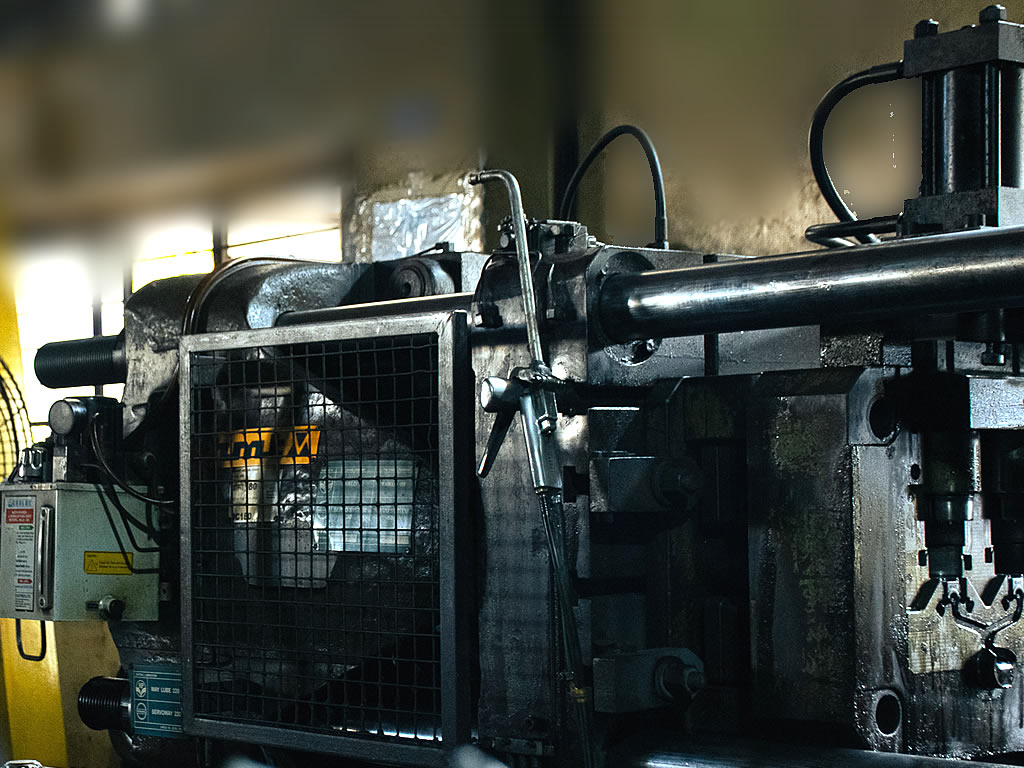

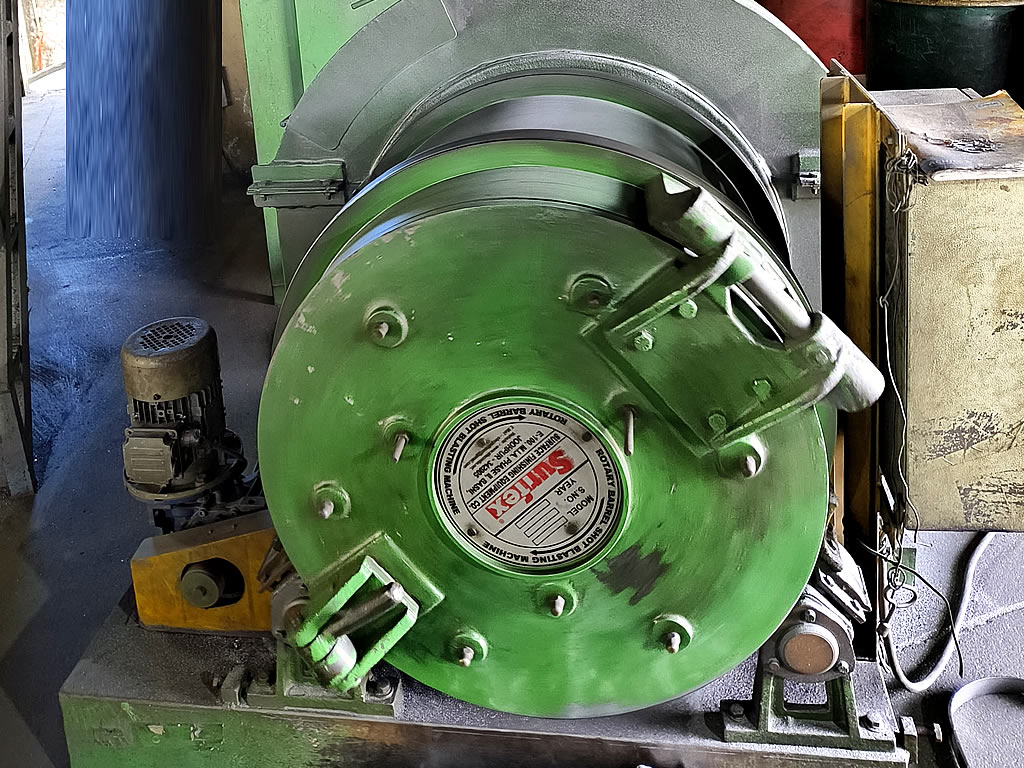

Our products under go mainly 4 stages of manufacturing such as Raw Material, Casting, Surface finish and machining.

Throughout the production journey, we adhere to a strict quality control procedure, conducting inspections at each stage right from

raw material procurement to the dispatch of the final finished products.